Web version from

Proceedings of Bridges 2003,

Sculpture from Symmetrically Arranged Planar Components

George W. Hart

Computer Science Department

Stony Brook University

Stony

E-mail:

george@georgehart.com

Abstract

The extended face planes of symmetric

polyhedra form a

set of interconnected canvases that can be used as the basis for a wide

range

of sculptural forms. A special-purpose software tool is described

which

allows the user to select families of such planes, to draw within them,

to

maintain constraints concerning points lying on their intersections, to

view

and modify the results interactively in real time, and to output the

result for

production either as 3D rapid prototyping or 2D laser-cutting,

etc. A

range of examples demonstrate the versatility of the approach.

1. Introduction

Artists

typically self-impose design constraints, challenging themselves to

explore new

possibilities in a restricted genre. I find myself fascinated by the

sculptural

possibilities inherent in symmetrically arranged intertwined planar

components.

Several of my sculptures are 3D forms assembled from flat parts that

lie in

symmetrically arranged planes. For example, Fig. 1 shows Twisted

Rivers,

|

|

|

|

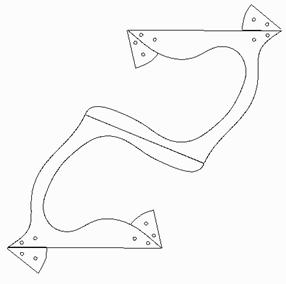

Figure 1:. Twisted Rivers, |

Figure 2: Layout for the 30 components of Fig. 1 |

The sculpture in Figure 1 is assembled from thirty identical curved units. Fig. 2 shows the flat layout for each of the thirty components, before folding the metal. I designed this sculpture by visualization, hand calculation of lengths and angles, and a series of paper models. Then I laid out the flat shape in a standard drawing program and sent the file to a laser-cutting service where the steel was cut on a computer-controlled laser cutter. I folded the parts to the proper angles in a hand brake then sent them out for the blue powder coating. Finally, I wove the thirty parts together and fastened them with stainless steel bolts. Ten pieces meet at each of the twelve junctions where the bolt patterns are visible. The twenty openings are three-fold "whirlpools". If one studies the sculpture in person, it is apparent that groups of three C-shaped curves each lie in a common plane. There are 20 such planes—the planes of an icosahedron.

Figures 3 and 4 show a second example, Fire

and Ice.

This is a 24" diameter hollow form, assembled from sixty identical

pieces

of red oak and ten interwoven loops of brass. These oak components were

also

hand designed using visualization and paper models, and laid out in a

general-purpose drawing program. I then used the file to guide

the

cutting on a computer-controlled router. The two long edges were

then

beveled at 45 degrees, and the short edge at 72 degrees. They fit

together as

they do because the 60 pieces lie by pairs in the 30 planes which are

extensions of the faces of a rhombic triacontahedron.

|

|

|

|

Figure 3:. Fire and Ice, oak and brass, 24"

diam., 1997 |

Figure 4: Layout for 60 wooden parts of Fig. 1 |

Fig

5 shows Whoville, a more complex example in which the planes of

the

sculpture's components lie in the planes of three concentric polyhedra,

an

icosahedron, a dodecahedron, and a rhombic triacontahedron. (At one

type of

joint, along the 5-fold arms, the form incorporates a gradual twist

from one

plane to another, rather than a fold.) This was designed by hand with

the aid

of paper models. For this sculpture, I cut, drilled, and textured

the

metal by hand, then assembled the parts with rivets.

These three examples are members of a rich

family of

possible forms that involve symmetrically arranged planar components.

Only

years after creating these works and others, did I gradually awaken to

the fact

that I could use a special-purpose piece of software to aid me in the

design,

layout, and rapid prototyping of new sculptures in this category.

After

deciding what features I wanted and planning a design general enough

for use in

many new forms, I wrote the program described in the following section.

|

|

|

|

Figure 5:. Whoville, aluminum, 35" diam., 1997 |

Figure 6: Template for paper model of Whoville |

2. A Sculpture Design Program

My

goal in writing this software is to have a tool which can help me

design,

visualize, and produce large sculptures assembled from symmetrically

arranged

flat pieces. The program's editing tools allow me to design and

position

different families of components lying in planes that I specify.

At the

same time, the program shows me a rotating image of the 3D

construction, which

changes instantly in response to my editing any of the planar

components. If I

wish to produce a physical model by stereolithography, fused deposition

modeling, or other 3D rapid prototyping (RP) technique, the program

outputs the

STL file for fabrication. When I have a design finalized, the

metal,

wood, or plastic components can be cut by machinery such as laser

cutters or

water-jet cutters, guided by the 2D layouts the program produces as DXF

files.

The software handles the mechanics of replication, maintenance of

symmetry,

plane intersections, lengths, dihedral angles, and so forth. I can

focus on the

design issues.

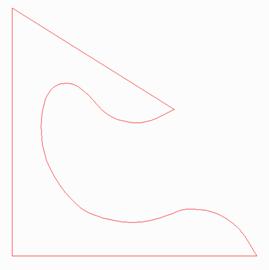

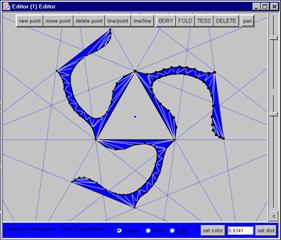

Figures 7 and 8 show the

user-interface. As

illustration, Twisted Rivers,

In the background of the editor window, one

sees

"guide lines"—the intersections of this one representative plane with

the other 19 in its family. (This arrangement of lines is known as the

stellation pattern of the icosahedron. [2]. Of the 19 other icosahedral

planes,

only 18 show up as lines, because the plane of the opposite face is

parallel,

so doesn't intersect this face) Over these guide lines, the user can

draw with

the mouse, insert, delete, and move points, connect points with edges,

etc. to

create a 2D layout. Each point can be specified as attached to zero,

one, or

two guidelines. The user's drawing is automatically replicated to

maintain rotational

symmetry in this plane. The toolbar controls the mouse function, and

with

sliders the view can be zoomed, rotated, and panned.

|

|

|

|

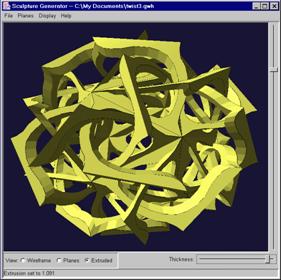

Figure 7:. 3D view window |

Figure 8: 2D editor window |

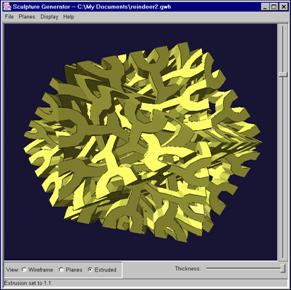

In

the 3D window, the user has the choice of three types of view:

wireframe,

planes, or extruded. Fig. 7 is the extruded view, which shows the

sculpture as having a slight (user-specified) thickness, exaggerated

here for

clarity. The 2D pattern is replicated 20 times, in the planes of

an

icosahedron's faces. Each plane is also doubled, to an inner and outer

surface,

connected with a thin edge. At edges where planes meet, the

representation ensures that the surface is "watertight" with no

gaps.

In this form, the model defines a volume, so it can be output as an STL

file

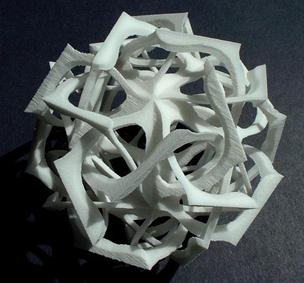

and fabricated by 3D rapid prototyping (RP) machinery. Figure 9 shows a

plastic

model produced from this STL output on a DTM Sinterstation 2500+.

|

|

|

|

Figure 9:. RP model of Twisted Rivers, 9 cm |

Figure 10: Tangled Reindeer, RP, 9 cm |

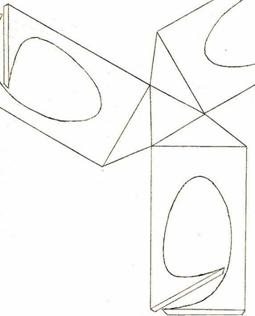

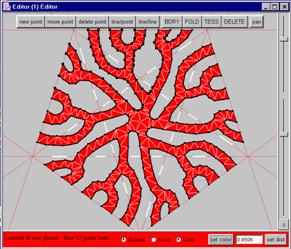

Figure 10 shows a

second RP

result from the program. This is a sculpture titled Tangled

Reindeer,

which is composed of twelve planar components in the planes of a

dodecahedron, though

it nestles nicely inside an icosahedron. The corresponding 3D window is

shown

in Figure 11, and the plan for each plane is shown in the editor window

of

Figure 12. (The background guide lines are now the stellation

pattern of

the dodecahedron.) The white segments in the editor are the

places where

the replicated structures in the other planes pass through this

plane.

The editor optionally shows these cut-through locations, so that one

can see if

the replicated parts will intersect each other.

|

|

|

|

Figure 11:. Tangled Reindeer, 3D view |

Figure 12: 2D pattern in one dodecahedral plane |

The

technical details of the software are beyond the scope of this paper,

but an

outline is as follows. Points are represented standardly as

floating-point

(x,y,z) coordinates, planes as normal vectors and distances, segments

as pairs

of points, etc. There are four types of points: "free-points" are

bound to a single plane and so are draggable in two dimensions,

"line-points" are bound to two planes and so are constrained to their

line of intersection, "corner-points" are fixed to the intersection

of three planes, and "center-points" are fixed at the center of

their plane. There are three types of segments: "boundary

segments", "fold lines" which lie in the intersection of two

planes, and interior "tessellation segments" which simply divide

polygonal regions into triangles because that is required for the STL

file

format. Symmetry and consistency are maintained, e.g., after a set of

planes is

created, the user can change their distance from the origin and points

on those

planes are projected to the new planes, points on the lines of

intersection are

projected to the new lines of intersection, and the guidelines on the

editor

windows move correspondingly.

At present, the extrusion process for

producing STL

files is simply radial in three dimensions from the origin. The

outer

vertices and outer surfaces are generated a few percent further from

the origin

than the inner surface. A slider in the 3D window controls this

percentage, which is 9%–10% in Figures 7 and 11. When extruding,

the

handedness of one set of triangles is reversed to maintain orientation,

and an

edge surface is created by generating a new pair of triangles for each

boundary

segment. This procedure has the advantages of being simple and

preserving

planarity. However it is inadequate in certain cases (not shown

in this

paper) when there are two families of planes of different distances and

the

outer surface of one meets the inner surface of the other. It also has

the

limitation that different families of planes are extruded to different

thicknesses. The further a plane is from the origin, the thicker its

extruded

version. However, this is not a fatal fault for a model intended

as a

prototype of the actual sculpture. More general extrusion processes

without

these limitations are planned for a future version of the software.

In Figures 8 and 12, only a few points

approximate

each curve, so the polygonal nature of the curves can be seen

easily. For

production, a more refined curve with many points could be drawn.

Instead, I take the program's 2D file output and convert it from a

segment

representation to a curve representation (cubic splines) in a standard

drawing

program. This second stage of the layout process is beyond the

scope of

this design program. In this second stage, tabs and bolt holes

might also

be added, as seen in Figure 2. Furthermore, the components might be

reorganized, again illustrated in Figure 2, where components from two

different

planes are joined into one piece, which is folded after cutting.

(The

bisecting fold lines are the outermost parts seen in Figure 1. An

alternative

would be to have a joining mechanism, e.g., bolts, along these outer

seams, but

I did not consider that visually appropriate.) Such aspects of the

design are

not within the scope of the program at this time, because the best

choice for

physically grouping components, e.g., tabs, folds, welds, bolts, etc.,

are

individual to each sculpture.

The software is coded in Java, with OpenGL

for the 3D graphics window. (At present there is no standard

binding for

using OpenGL with Java. I chose the GL4Java

binding, which

appears to be popular and stable.) I have been running the program on a

PC under

Windows, but as it is written in Java, it should be directly

transportable to other machines and operating systems. It

responds

instantly, changing the 3D view appropriately when any 2D view is

edited.

3. New Acrylic Sculptures

This

section shows four examples made from laser-cut acrylic plastic, i.e., Plexiglas.

In each case, the completed sculpture is shown at left and a single

component

at right. To make wooden or Plexiglas models, the 2D layout is output

as a

DXF-format geometry file used to cut the shapes. After cutting,

the parts

that mate are mitered so they can butt at the proper dihedral

angle. (The

dihedral angles are output separately by the program. For a metal

sculpture,

these angles are the fold angles, or could be used to set jigs that

hold pieces

in relative position for welding or brazing.) Then the parts are

then

intricately interwoven (which usually took several hours) and glued

with a

solvent cement.

|

|

|

|

Figure 13:. Deep Sea Tango, 15 cm |

Figure 14: One component of Fig. 13 |

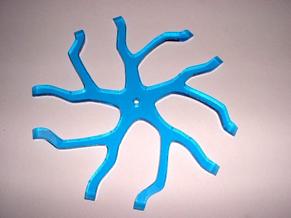

Figures

13 shows Deep Sea Tango, which can be thought of as twelve

starfish-like

forms "holding hands" in a complex ballet position. It is

assembled from twelve identical parts, each as in Figure 13, which only

touch each

other at their tips. Because of the transparent material, it is

difficult to

capture in a photograph how the many arms just manage to pass by each

other at

various angles. The design is based on the great dodecahedron,

and

conceptually very similar to Tangled Reindeer, (cf. Figures

10-12) but

twelve rigid parts shaped like Figure 12 could not be assembled because

they

would block each other's movement. These parts (Figure 14) have

much less

branching, but even so, it is just barely possible to assemble them.

|

|

|

|

Figure 15:. Quintessence of Hedgehog, 15 cm |

Figure 16: Two shapes of components for Fig. 15 |

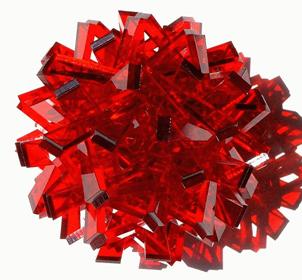

Figure

15 shows Quintessence of Hedgehog, which contains twenty-four

windmill-like

parts, twelve in each of two slightly different 5-fold shapes.

They lie

in the face planes of two concentric parallel dodecahedra. The larger

parts lie

in the planes of the smaller dodecahedron as they have to extend

further to

reach the circumsphere where the two types of parts meet. The

sixty

junction points are each the meeting of one large arm and one small

arm. (The

design program allows the user to create several editor windows, each

like

Figure 12. The intersection lines of each plane with all the other

planes are

color-coded to distinguish the different families. Points on the

lines of

intersection of two families show up in both editors, and if dragged in

one

plane make the corresponding motion in the other plane.)

|

|

|

|

Figure 17:. This End Up, 23 cm |

Figure 18: One component of Fig. 17 |

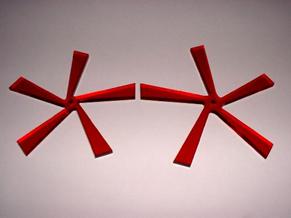

Figure

17 shows This End Up, which contains twenty parts of the form

shown in

Figure 18, lying in the planes of an icosahedron. The parts pass

around each

other without touching, except for where they are joined at the arrow

tips in

groups of four. The structure is based on the uniform compound of

five

regular octahedra, which is one of the stellations of the icosahedron.

It

took almost two hours for me and ten members of the Stony Brook

University math

club to assemble this. I originally thought that ten people could each

hold two

parts and translate them all together "from infinity" but we couldn't

get the interweaving just right, and we eventually found a less

systematic

assembly method which did work.

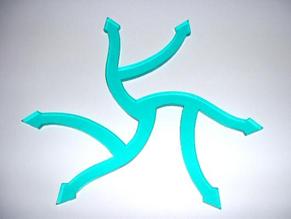

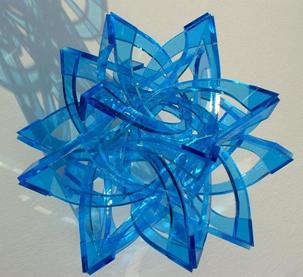

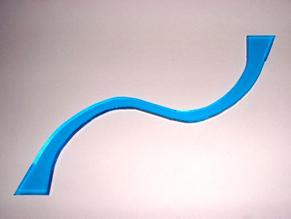

Lastly,

Figure 19 shows Bouquet, which contains thirty S-shaped

parts as

shown in Figure 20. The components lie in the face planes of a

rhombic

triacontahedron, but the viewer sees it as a dozen flowers that nestle

inside a

dodecahedron. The ends meet in groups of three, but in the

interior the

components make 5-fold spirals without contacting. Because of the long

thin

parts, this sculpture is slightly flexible.

|

|

|

Figure 19: Bouquet, 23 cm |

Figure 20: One component of Fig. 19 |

4. Conclusions and Future Work

For several years I have been exploring a

space of

forms with symmetrically arranged planar components. [3] I find that

they can

be visually and intellectually engaging, with a rich mix of simplicity,

complexity, geometry, and an organic quality. (In addition, a

practical

benefit of this class of sculpture is in transportation: One can ship

the parts

of a large work as a flat package and assemble them on site.) To

explore further

in this family, I created a design program to virtually prototype new

works. This real-time explorer of spatial ideas allows for more

complexity than my previous sculptures, permitting intertwined

relationships

between several families of planes. It encourages experimentation while

handling the computational issues of maintaining symmetry, planar

intersections, and layout.

As an interactive sculpture design tool, it

was

inspired in part by Sequin's tool for generating sculptures in the

style of

Brent Collins. [4] The program presented here is in some ways

analogous, but

with a different family of forms. There are a number of previous

programs which

allow the user to design stellations, e.g., [1] and [5], but as far as

I know

no previous work allows freeform design in the stellation planes.

This is an ongoing project with many future

directions, mainly additional sculptures. I also have a list of

software

enhancements to add, such as other forms of extrusions, and edge

treatments for

the RP results.

References

[1] V. Bulatov, "An Interactive Creation of Polyhedra Stellations with Various Symmetries," Bridges 2001: Mathematical Connections in Art, Music and Science, Reza Sarhangi (editor), 2001.

[2] H.S.M. Coxeter, P. DuVal, H.T. Flather, and J.F. Petrie, The Fifty-Nine Icosahedra, U. Toronto Pr., 1938, (Springer-Verlag reprint, 1982), (Tarquin reprint, with additional images, 1999).

[3]

G.W. Hart, see list of references at http://www.georgehart.com

[4] C.H. Sequin, "Virtual Prototyping of Scherk-Collins Saddle Rings" Leonardo 30:2, pp. 89-96, 1997.

[5] R. Webb, "Stella: Polyhedron Navigator," Symmetry Culture and Science, 11, No. 1-4, pp. 231-268, 2000/2003.

Acknowledgments: Thank you Jim Quinn for the RP

production, and

Chris Palmer for the laser cutting.

Addendum: For more pictures and info about the acrylic

sculptures, click

here.